Description

Rotary lobe pump Features:

1.Stainless Steel sanitary rotary lobe pump belongs to positive displacement pump and has the advantages of outstanding self-priming ability, high efficiency, and long life.

2.It applies to delivering suspension liquid with soft solid particles, corrosive medium and suspension liquid.

3.The delivered medium temperature range from -30~150℃(with water washing mechanical seal, pump can bear 200 degree) and viscosity range from 30cst to 1.0×105cst.

4.The parts of contact with medium adopt stainless steel.

5.The rotating speed can be adjusted according to the delivered medium's physical property.

Rotary Lobe Pump Application:

1.Dairy products: yogurt, cream, ice cream, cheese and whey.

2.Beverages: beer, wort, yeast, soft drinks, fruit concentrates, fruit drinks.

3.Food: tomato sauce, vegetable paste, seasoning, sweeteners, yeast paste, salad, meat emulsion, edible oil.

4.Candy: syrup, cream stuffing, fruit puree, fruit filling, pudding, jam, jelly, chocolate.

5.Cosmetics: creams and lotions, hair gels, hair dyes, essential oils.

6.Drugs: Pill, extract, emulsion, paste.

7.Chemicals: fats, solvents, resins and polymers, dyes...

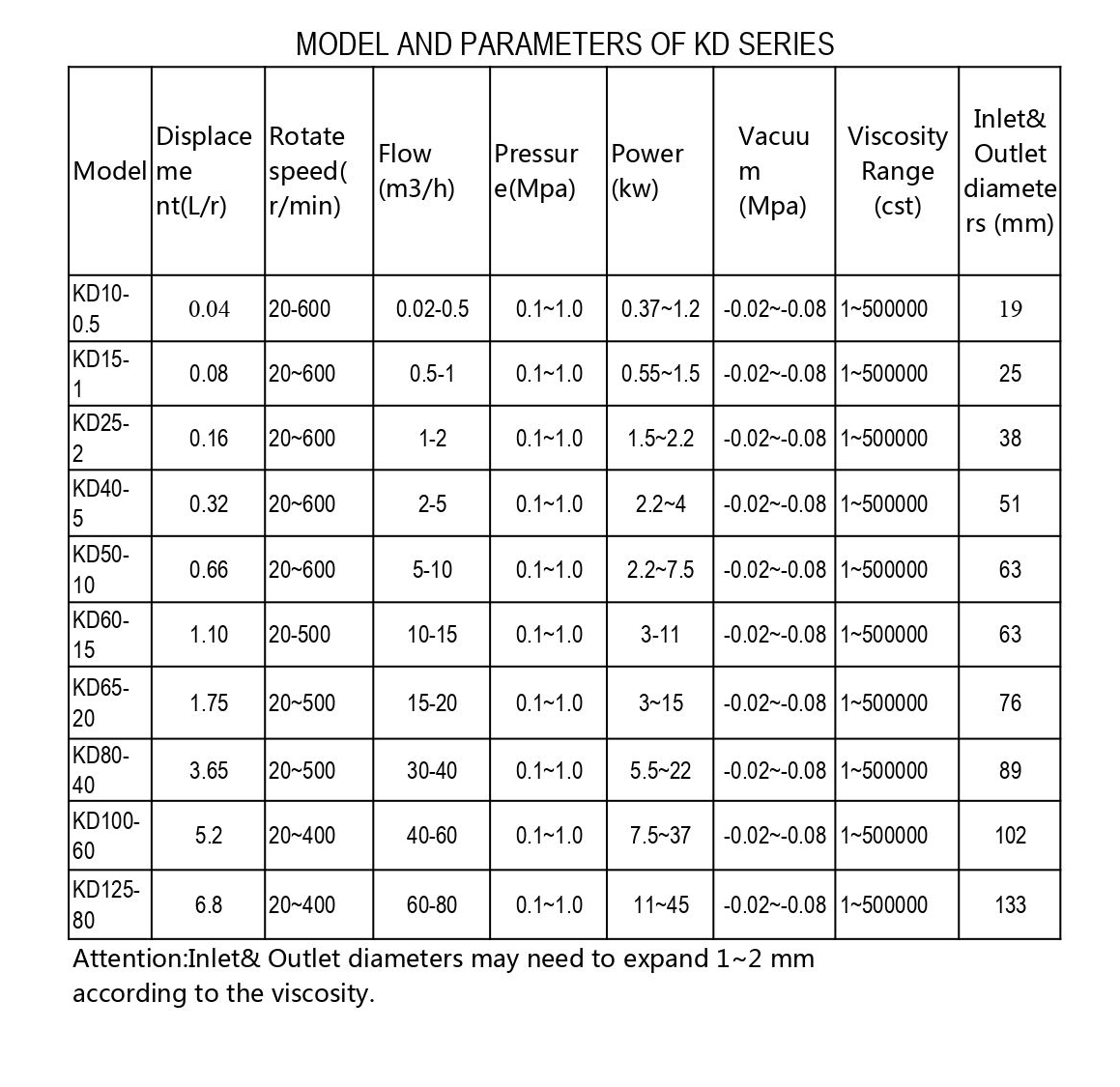

Rotary Lobe Pump Technical Specifications:

1.Maximum flow: 90 m3/H

2.Maximum pressure: 20 bar3.Maximum temperature: 150℃

4.Maximum speed: 750 RPM

5.Material: 304/316L

6.Inner surface: Ra 0.8 m

7.Certification: 3-A-02-11 No.1579; CE - MD / 06-42; 177.2600 the FDA.

8.Import and export connection: 1) horizontal TUL 2) vertical TUR

9.Butterfly rotor (standard); Five-leaves rotor; Three-leaves rotor; Two-leaves rotor; Single butterfly rotor

10.Machine seal: Single end face machine seal (standard), double end face machine seal (optional), Material SIC/SIC,TC/TC

|

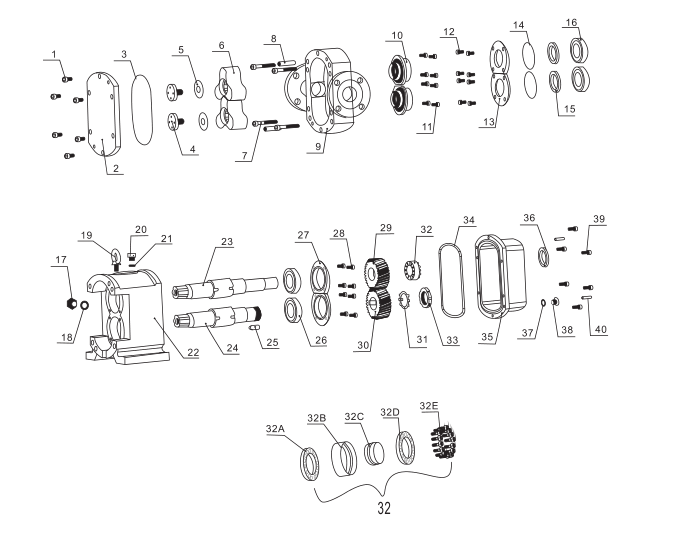

1.Screw |

2.Pump cover |

3.O-ring |

4.Rotor locking screw |

5.Butterfly spring

|

|

6.Rotor |

7.Screw |

8.Positioning pin |

9.Pump body |

10.Mechanical seal |

|

11.Screw |

12.Screw |

13.Front axle cover |

14.O-ring |

15.Skeleton oil seal |

|

16.Bearing |

17.Oil sight glass |

18.O-ring |

19.Screw rings |

20.Breathable plug |

|

21.O-ring |

22.Gearbox |

23.Spindle |

24.Counter shaft |

25.Flat key |

|

26.Bearing |

27.Rear axle cover |

28.Screw |

29.Gear |

30.Gear |

|

31.Stop washer |

32.Expansion sleeve |

33.Gear lock nut |

34.O-ring |

35.Rear cover box |

|

36.Skeleton oil seal |

37.O-ring |

38.Oil drain plug |

39.Screw |

40.Positioning pin |

F.A.Q.

|

1. Q: Do you have a factory? |

|

A: Yes, we do. We have our own factory base.

|

|

2. Q: How long is the production cycle? |

|

A: It depends on the machine.The fastest delivery time is within a few days, and the longest delivery time is twenty days. |

|

3. Q: Is there a warranty period? |

|

A: Yes,the warranty period is one year. |

|

4. Q: Can the machine be customized? |

|

A: All machines can be customized according to the customers' needs. |

|

5. Q: Can I have a free sample? |

|

A: Yes, you can. Free samples or discount can be provided for our first friendly cooperation. |

|

6. Q: Do you have technical guidance? |

|

A: We have professional teams to offer great technical guidance.We can offer free video call to solve technical problems. |